The AI-driven path to sustainable logistics: The promises of simulation

“If people do not believe that mathematics is simple, it is only because they do not realize how complicated life is.”

― John von Neumann

All companies within a supply chain—whether e-commerce businesses or carriers—need to mitigate risks arising from network changes or abrupt shifts in demand. While such changes aren’t always predictable, businesses can still prepare. How? The answer is simulation.

What is simulation, and how can it promote sustainable logistics?

Simulation is the key to flexibility and resilience. Simulation is the act of modeling events or data to help companies forecast results and plan accordingly.

A snowstorm or hurricane can alter the courses of carriers and millions of packages. Simulation can enable short-term flexibility by predefining more efficient plans beyond Plan A or B.

Simulation is especially useful for long-term flexibility. Logistical networks should be resilient against surprises and massive market changes. For example, one of the consequences of COVID-19 is an air-traffic shift from business-class passenger flights to freight transport. How can the transport infrastructure absorb such a game-changing situation for the type of traffic?

At Quincus, we develop reinforcement learning algorithms that focus on simulating operations inside a network for long periods. This helps conceive new business models, technologies, and networks backed by data and metrics.

How does simulation impact sustainability and resilience?

Simulation has the potential to transform the current paradigms. For one, transport infrastructures could be planned, designed, constructed, and operated to mitigate climate impact, protect biodiversity, and minimize pollution. To test a carrier’s carbon footprint, you need a system to model months and years of operations in hours and days. Modeling can convey the impact that adding drones and more mid-size hubs, giving up hub and spokes strategies, or buying new vehicles can have on an operation’s sustainability efforts.

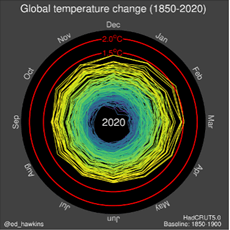

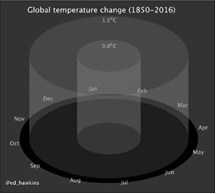

Climate resilience is also crucial. The climate spiral in Figures 1 and 2 depict how global temperature has increased over the last twenty years. A logistical network should go beyond simply adapting to a one-time event. It needs the inherent flexibility to adapt to a rapidly evolving ecological situation. McKinsey Global Institute predicts that the global average temperature will climb between 1.5°C and 5°C over the next three decades. There’s over a 15% probability of increasingly extreme temperatures during the summer months.

With disruptions and extreme weather events, such as fires across Western North America, droughts, floods, and hurricanes all over the planet, companies with enormous resources like Amazon or Alibaba.com need ways to anticipate climate change effects. Could rising sea levels impact the busiest ports? Tough decisions, such as modifying network hubs could impact costs, profitability, and the environment. But even more, could they worsen climate change or bring some hope?

Without simulation, companies approach these concerns without direction—a shot in the dark. Run experiments, observe the outcomes, prototype, and test effectively.

How simulation works in logistics

If your company acted on every assumption, you’d spend millions of dollars and countless months to collect enough usable metrics. That’s a lot to gamble on. Instead, we can compress eighteen months into one hour.

Simulating reality is not enough. We need to do so at faster-than-real-time rates. In the example above, we’d need an acceleration of 12,960x, using the right combination of hardware and ad hoc algorithms. At Quincus AI, we get our inspiration from the work in autonomous vehicles and video games. For example, Waymo combines the power of its in-house tensor processing units (TPUs) with its state-of-the-art algorithms (a combination of imitation learning and reinforcement learning) to build learning driving agents from simulation.

Sustainable logistics goes beyond carbon emissions

A sustainable network can reach any population anywhere on Earth. Riders for Health, for instance, is an NGO that supplies, manages, and maintains vehicles for health-focused organizations in Africa. They’ve innovated an efficient way to bring medicines and vaccines to any village in Africa, despite road conditions. They use motorcycles, even hacking some to pump water. While innovative, the critical success factor of such a model is its efficiently designed bike network.

Riders for Health’s founders managed to build a successful model thanks to their experience in Africa. But many startups and NGOs don’t have the resources to take risks with innovation and fail due to lack of experimentation. Simulation can help ensure no individual or community is left behind or cut off from basic needs like food, education, and health.

We at Quincus know that simulation can help design the most efficient delivery networks. Put yourself in your customers’ shoes; simulation is the key to better inclusion.

Stay tuned for the final part of our series on sustainable logistics.

Learn more about how Quincus is driving innovation across the supply chain.

Generate your solution

Written by Christophe Pennetier

Continue reading:

Part 1: The AI-driven path to sustainable logistics

Part 2: The AI-driven path toward sustainable logistics: The impact of optimization

Part 3: The AI-driven path to sustainable logistics: The promises of simulation

Part 4: The AI-driven path to sustainable logistics: A new paradigm in logistics

Subscribe to keep up with our latest news